The Vertical Gun Range¶

This facility allows investigating impact cratering from projectiles launched from 80 to 600 m/s. Small projectiles ranging from a few mm to 1 cm in diameter can be fired using a high powered air gun. The gun design is such that a rapid and uniform pressure rise is generated by our launch mechanism to maximize the launch speed. Sabots are fired to launch projectiles and block gas flow that follow the projectile. Such gas flow has frequently been an issue with both air guns and single- and multiple-stage light gas guns for vertical impacts.

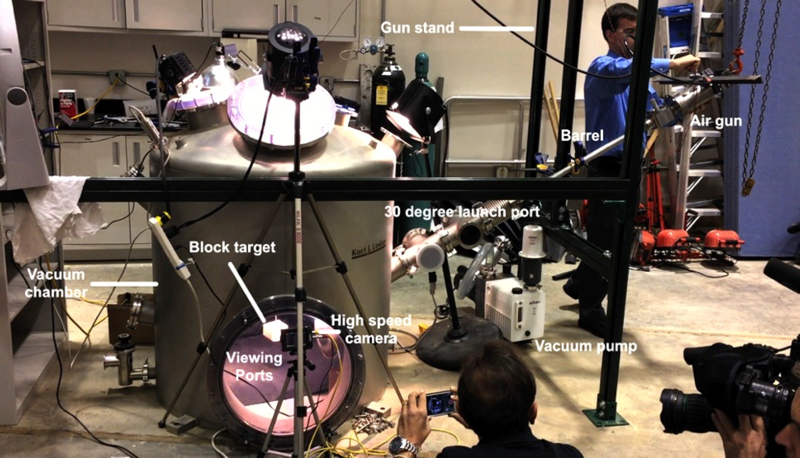

The PIL’s Vertical Gun Range¶

The test chamber is large, with a base circumference of 1 m and a height of ~1.5 m. Several view ports allow the researcher to view experiments with high-speed cameras, provide appropriate lighting, and install diagnostics such as laser sheets. Each port ranges in size from 20 to 50 cm in diameter and is covered by 1-inch-thick Plexiglas. The chamber can be placed under various planetary (e.g., Mars, Earth) and vacuum conditions (<10 Pa, but highly dependent on the target materials employed). It also possesses several ports that allow the barrel to be placed at multiple angles: both vertical and oblique impacts can therefore be investigated.

The diagnostics available include several high-speed cameras (Vision Research Phantom v12 - from JHU/HEMI - and Miro 4 from JHU/APL) permitting visualization of various cratering and fracturing processes from 1000 to 1,000,000 frames per second. Laser sheets are available to accurately measure the displacement of a target surface during impact, and particle interferometry software is available for measuring the velocity and displacement of ejecta and disruption fragments from the high speed video. Pressure and strain gauges, as well as high-speed analog-to-digital converters can be used to measure pressure changes and stress within a target, or experienced by a container holding the target material.

Impact Cratering Data Sets¶

Below find various data sets collected by APL staff and their colleagues.